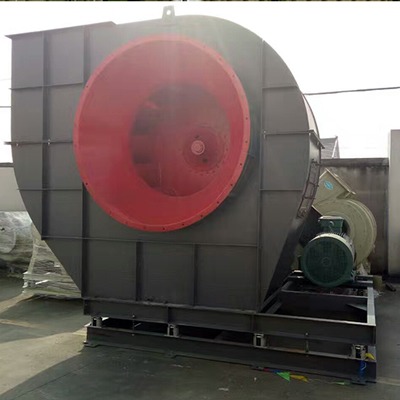

Technical parameters of boiler centrifugal ventilation fan:

Fan model: TPC14C

Fan air volume: 100000CMH

Fan pressure: 4000-5000Pa

Balance level: ≤ G2.5 mm/s

Fan efficiency: ≥ 84%

Operating temperature: ≤ 80%

Fan speed: 1315rpm

Motor power: 220KW

Air duct diameter: DN1300~DN1400 M

Applicable location: metal processing plant

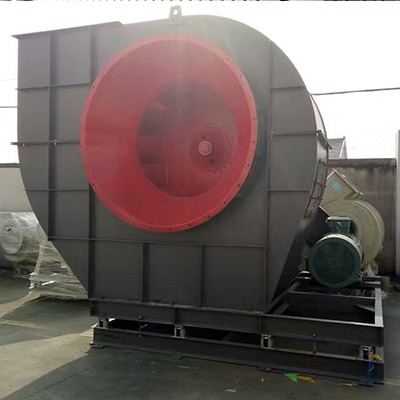

Industrial fans are widely used in fiberglass processes, rare earth extraction, chemical and pharmaceutical industries, wastewater deodorization, anaerobic papermaking, acid recovery and utilization, and other environments containing high-pressure corrosive gases. Industrial waste gas treatment centrifugal fans have a wide range of applications, are suitable for various working conditions, are efficient and energy-saving, and create profits and save costs for you.

The use of direct connection between motors and impellers reduces ventilation resistance losses such as S-shaped ducts, improves efficiency, and also reduces safety hazards and maintenance troubles caused by S-shaped ducts, improving operational safety.

Select a high-quality explosion-proof motor specifically designed for fans, and place the motor in a flow isolation chamber with certain voltage resistance to isolate it from the gas containing airflow in the mine. The flow isolation chamber is equipped with an air duct that automatically ventilates with the atmosphere, facilitating heat dissipation and flow guidance.

Widely used in fiberglass processes, rare earth extraction, chemical and pharmaceutical industries, wastewater deodorization, anaerobic papermaking, acid recovery and utilization, and other environments containing high-pressure corrosive gases. Industrial fans have a wide range of applications, are suitable for various working conditions, are efficient and energy-saving, and create profits and save costs for you.