高温玻璃钢风机的光滑油变质或商标不对,粘度太低或太高。一般风机的光滑油尽量半年更换;

高温玻璃钢风机的光滑油量不足或过量。风机多为循环油,光滑站的压力和油温对轴承座温度影响很大。稀油站的油泵的压力一般为0.15~0.2MPa,油泵温度不高于40℃。应定时清洗油过滤器。

与此同时,进管道和回管道间隔机壳不适合太近,避免工作温度的幅射影响油温;高温玻璃钢风机的工作温度太高。风机轴承座温度随工作温度起伏较大,加工工艺操作不稳定,导致风温不稳定,进而影响轴承座温度。

高温玻璃钢风机的装置误差。两端轴承装置不同心或由于主轴装置定位的误差,造成非定位端轴承座端盖与轴承外环空隙太小,主轴受热胀大后,轴承外环与端盖产生冲突等都会导致轴承发热;

玻璃钢风机的轴承磨损严峻,轴向及径向游隙过大。这主要是轴承使用时间过长,滚珠和保持架等磨损严峻,需要更换。

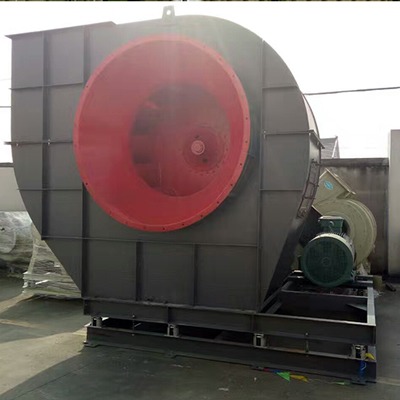

这章讲述,由《江苏磐力环保设备有限公司》的分享经验,质量诚信3A品牌企业,二十年行业实战经验专注风机生产厂家,五轴雕刻工艺,ISO质量认证9001:2015,增加项目工程档次,每小时省电20%,1对1设计服务,提供海拔方案设计,我们运行平稳的产品,协作共赴,及时处理的问题,立即垂询: 0512-82870668。

Enquiry hotline

0086-512-86878095 18351783102