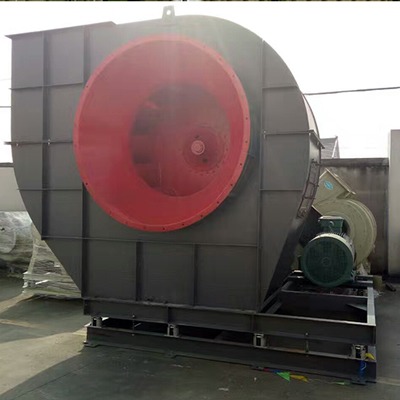

工厂用锅炉离心通风机长时间运转会加剧叶轮的磨损,为了降低置换成本,对叶轮进行修理是需要的,如何进行现场修理呢?

首先切除离心通风机叶片磨损部分后,用砂轮将叶片切平,去除毛刺,打磨30度的倒角。

通过测量,每片叶片焊接5根4根。要求双面焊接。焊接前,需要准备材料和叶片。焊接时,每片叶片先焊接一根焊条,再焊接另一片对称叶片。其目的是避免锅炉离心通风机局部焊接过热,造成叶片变形。

焊接的焊缝不得有气孔和砂眼。焊接叶片后,对焊缝进行渗透和检测。检查离心通风机前喷洒清洁剂,然后涂抹渗透剂,喷洒显示剂。如果发现裂缝,用砂轮打磨焊缝,然后重新焊接。

焊接叶片后,焊口应退火。采取以下措施:用气枪加热焊口200~300°℃,均匀烘烤2~3min。

修好叶片后,在备料工作面上堆焊抗磨层。需要就绪后,可以启动锅炉离心通风机试运行,看是否有异常

这篇讲述,是磐力风机生产厂心得分享,优质服务守信3A品牌企业,10年专注于风机开发20000m²生产地,纯玻璃钢生产制造,风机进风口消音装置,生产周期短2天内交货,风机效能+10%,急单出货2天内,提供防腐设计方案,保障以合理的设计理念发明,求实共赢,被困惑的问题,欢迎垂询: 0512-82870668。

Enquiry hotline

0086-512-86878095 18351783102