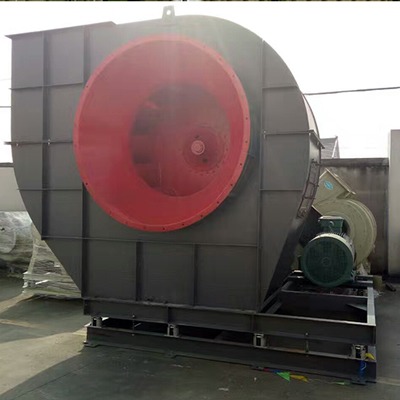

Anti-corrosion FRP fan technical parameters:

Fan model: GFB630C

Transmission mode: belt drive

Fan air volume: 10996~20477 CMH

Fan pressure: 2823~1433 Pa

Operating temperature: ≤80℃

Fan efficiency: ≥82.3%

Vibration value: ≦2.5mm/s

Fan speed: 1870rpm

Motor power: 15KW

Air duct diameter: DN600 [Recommended with PVC shock absorber soft connection]

01CQC Energy-saving product certification

Anticorrosive fiberglass fan test in line with GB19761-2009 national standard, fan manufacturer equipment, CQC China energy-saving product certification, continuous operation of 24 hours troublefree operation, maintenance and long service cycle, energy saving, the whole unit testing computer stress and strain analysis, stable fan operation.

02 Material accessories selection

OIL bath closed bearing seat, lubricating protection bearing, and shaft core is not corroded by corrosive gas, wear resistance, strict quality control, reduce the frequency of failure, modular production, unified specifications, complete parts and materials, support 2 days fast delivery, reduce operating costs, ensure installation and use.

03 Provide service team

Support on-site measurement of fan performance, vibration, noise and other tests, including test reports, and a number of delivery data is complete, prevent failure before it happens, ensure that the fan operates in the best condition, tailored for users to ensure that the fan operates at the best efficiency point, avoid surge damage area.

Anti-corrosion FRP fan can be widely used in pharmaceutical and chemical industry, precision electronics, metal processing, PCB circuit board, sewage deodorization, semiconductor process, electroplating pickling and other places containing acid and alkali components and chemical composition of corrosive gases. Anticorrosive fiberglass fan has a wide range of applications, suitable for a variety of working conditions, efficient energy saving, create profits for you, save costs.