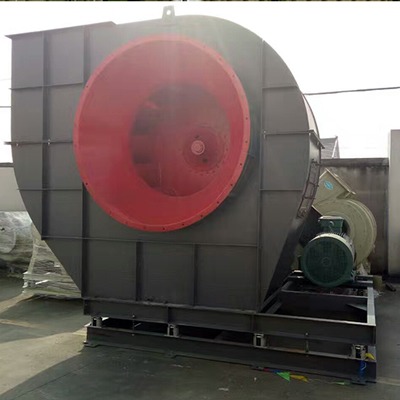

Fan parameters for fiberglass deodorization tower:

Fan model: FB 800C

Fan air volume: 16141-32566 CMH

Fan pressure: 3031-1830 Pa

Rotor balance: ≤ 2.5 mm/s

Unit vibration: ≤ 4.5 mm/s

Operating temperature: ≤ 80 ℃

Fan efficiency: ≥ 82.2%

Fan speed: 1710 rpm

Motor power: 30KW

Air duct diameter: DN700~DN900 mm [odor and leakage prevention design]

The fiberglass fan of the soundproof box meets the noise standard limit. The fan equipment runs continuously for 24 hours, with low noise, low vibration, glossy appearance, and energy saving. The soundproof box is recorded according to computer testing standards, and actual measurement noise analysis is conducted to improve the overall sound insulation effect of the fan.

The D-type pipeline inspection is carried out using a centrifugal fan, which complies with the GB-T1236-2000 air duct inspection standard. The centrifugal fan casing and impeller are comprehensively manufactured, with an oil bath rolling bearing box and an air-cooled refrigeration method. The industrial production has the same specifications, convenient operation, fast time, low usage cost, and centrifugal fan replacement.

Xinyue, with advanced technology in fiberglass fans and experienced senior experts; By combining precise data calculation, research and development technology CAD, SolidWorks 3D, CFD and other simulation data collection software, we can customize the design and simulation effect to ensure that the centrifugal fan meets the design specifications and standards.

The fan products for fiberglass deodorization towers are mainly used in places with corrosive gases containing odor and chemical components, such as sewage deodorization, biological deodorization, garbage deodorization, and food deodorization. The box design can reduce noise by 5-15 decibels, mainly to prevent secondary odor emissions, effectively block odor, and be covered by the atmospheric atmosphere, affecting the surrounding environment, especially in residential areas, reducing a lot of influence.