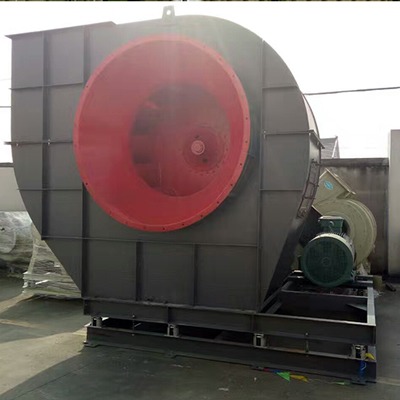

Explosion proof centrifugal fan parameters:

Fan model: TPE 16C

Fan air volume: 71584~106208 CMH

Fan pressure: 4410~3346 Pa

Balance level: ≤ G2.5 mm/s

Operating temperature: ≤ 80 ℃

Fan efficiency: ≥ 85.2%

Fan speed: 900rpm

Motor power: 132KW

Air duct diameter: DN1300~DN1500 mm

Transmission unit: BT4 explosion-proof variable frequency motor [supports brand designation]

The raw materials are Q235A/B, with a temperature resistant and anti-corrosion coating, and production technology from the source. Combined with research and development of fireproof flower design, customized according to needs, cost optimization, suitable for various flammable and explosive environments such as ventilation, chemical, electroplating, biological and sewage deodorization.

11 manufacturers provide design solutions and technical consulting services, conduct on-site surveys, regularly inspect the operation status of fans, promise one-year warranty free, lifetime warranty, nationwide logistics delivery, and provide on-site guidance and installation training.

Explosion proof centrifugal fans are mainly used in places without acidic or alkaline components such as pharmaceuticals, petroleum, chemical, electronics, metal processing, PCB circuit boards, electroplating, and other flammable and explosive gases. They are also suitable for various working conditions such as exhaust and air supply in multifunctional applications. The fan operates smoothly, increasing profits and saving costs for you. They are the preferred choice for centrifugal fan models.