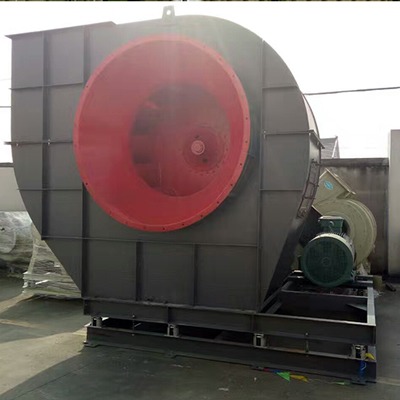

Technical parameters of high-pressure centrifugal ventilation fan:

Fan model: THPB 11.2C

Fan air volume: 11157~21713 CMH

Fan pressure: 7746~6172 Pa

Balance level: ≤ G2.5 mm/s

Fan efficiency: ≥ 84%

Fan speed: 1550 rpm

Motor power: 55KW

Air duct diameter: DN500~DN600 M

Altitude standard: 101325 N/㎡

Transport medium: exhaust gas or air [thickened anti-corrosion paint coating]

The shell of the fan is welded into one piece, increasing the strength of the shell. The fan equipment runs continuously for 24 hours without damage, with a long service life, energy efficiency, and electricity saving. The entire unit is tested and subjected to stress-strain analysis to improve product safety.

Adopting a well shaped reinforcement, it is aesthetically pleasing and durable. The unit adopts an oil bath enclosed oil tank to reduce the frequency of malfunctions. Mechanized production, uniform specifications, complete parts and materials, and can complete installation and maintenance in the shortest possible time and at the lowest cost.

We provide professional technology to solve user problems, conduct regular equipment operation status surveys and inspections, conduct customer satisfaction surveys, and provide valuable opinions or suggestions to our company to ensure that the fan operates in the best condition. We can tailor the design to the special specifications of customers to ensure high fan operation efficiency.

High pressure centrifugal fans can be widely used in dust collection, incinerator exhaust, VOC organic exhaust, high-temperature exhaust, semiconductor process, and forced air supply; Widely applicable, suitable for various working conditions, efficient and energy-saving (energy-saving), creating profits, saving costs, and providing after-sales service for you.

The THPB series high-pressure centrifugal fan can be used for blowing and conveying air and non corrosive, non self igniting, and non viscous gases in furnaces and forging furnaces. However, the temperature of the conveying medium should not exceed 80 ℃, and the dust and hard particles contained in the medium should not exceed 150mg/m3; Widely applicable, suitable for various working conditions, efficient and energy-saving, creating profits and saving costs for you.